Bulk Density meter

A little bit of history

The Bulk Density meter is a device that we developed in 2000 used for measuring the bulk density of substrates and peat during production. But first some history about the Bulk Density meter.

Measuring the bulk density according to the European standard EN12580 is common sense in the peat and potting soil industry. In the year 1999 the European growing media industry agreed that peat and potting soil must be traded based on Bulk density and volume. In short: ENm³-volume instead of m³-volume (water-volume). The reason for this was that there were too many discussions about if the right amount of product was delivered to the buyer. When a truck was completely filled at the manufacturer’s factory, it depended on the distance travelled how optically the filling of the truck was upon arrival at the customer. Was the travel over a nice road the truck was optically completely full. But if the road was not so flat and nice the top level of the product on the truck was lowered and thus more compressed at arrival due to vibrations and optically not fully filled. Trading in ENm³-volume would make an end on the discussions.

The industry was already used to measuring the bulk density by hand. A heavy work, time consuming, inaccurate method with a 20 liter cylinder and several screens resulting 1 or 2 measurements per batch.

European Standard EN12580 describes in detail how to measure the bulk density of your soil. The method uses screens with different mesh width, dependent of the product you want to measure. The purpose of the screen is to prevent the soil from falling from such a height, that the soil which is already in the cylinder will be compressed due to the impact of the falling soil. The screen also regulates the amount of soil which can fall at a specific time as a whole in the cylinder. Due to this method, the cylinder will be filled as homogeneous as possible.

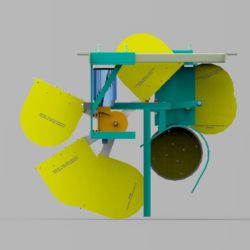

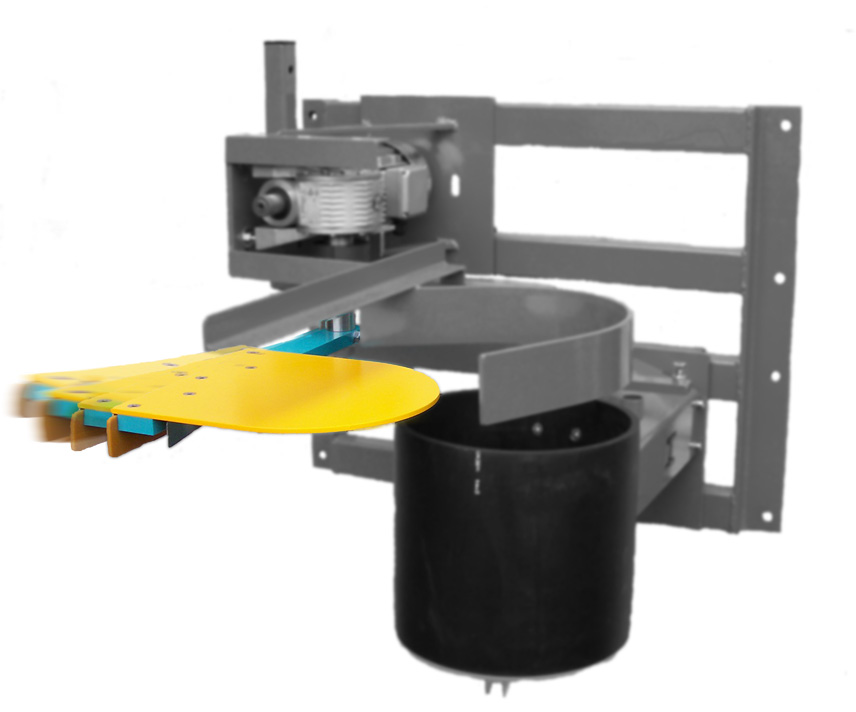

The INADCO Densimeter

The INADCO Densimeter is a bulk density meter that consist of 3 major parts. A measuring module and a motor module. Both attached to a sub-frame.

The sampler module is an electronic driven shovel that rotates through a falling product stream and, in that way, collecting a small sample of product.

The measuring module consist of a cylinder with the same volume as the cylinder used in the manual EN12580 method. The measuring cylinder is mounted on a weighing cell.

With adjustable scoop rotation, the sampler takes samples from a vertical product flow. The shovel shall bring the collected sample toward the measuring cylinder where it will be obstructed so it shall fall in the measuring cylinder with zero vertical velocity as a starting speed. The sample taking will be repeated until the measuring cylinder is completely filled. The sample taking will pause and after the calculation of the Bulk Density the shovel shall rotate over the measuring cylinder to open the bottom. All the collected sample will slide out the cylinder back into the main product stream. The shovel shall rotate back closing the bottom and starts again with the sampling. The time consumption of the sampling, calculation and emptying is around 60 seconds resulting in a measurement every 3-5 m³ of product. A much higher rate compared to the manual method.

Advantages

Fully automatic

Consistent

Maintenance free

Accurate

Bulk Density meter in action

Bulk Density measurement in potting soil

The INADCO Densimeter is mounted in a factory that produces potting soil, bases on mixtures of various types of peat, fertilizers and other additives.

Due to the reproducing method of sampling and the used measurement volume, this results in a high quality of moisture measurement, which in turn ensures a better quality of the potting soil.

Introduction of the Bulk Density meter

The introduction of the Bulk Density meter in 2000. Combined with an INADCO Beltweigher for measuring the EN-Volume of potting soil.

Technical information

Some specs

|

|

Minimum

|

Maximum

|

Unit

|

|---|---|---|---|

|

Bulk Density

|

20

|

2000

|

g/l

|

|

Volume Cylinder

|

-

|

20

|

l

|

|

Power supply

|

-

|

240

|

V

|

|

Power consumption

|

100

|

250

|

W

|

|

Measuring cycle

|

45

|

70

|

sec

|

Available options

Moisture Sensor

Potting Reference

Higher speed

Cleaning

Mobile

Do you have any questions?

Contact us and we shall help you!!